Revolutionising Lithium Recovery with Cost-Effective, High-Performance Technology

At Geo40, we’ve developed groundbreaking Direct Lithium Extraction (DLE) technology that delivers high performance at a low cost, unlocking new opportunities for lithium recovery.

Since early 2024, our third-generation pilot plant has been on the road, proving our technology’s suitability across the key North American lithium-bearing oil and gas formations.

Join us as we pioneer the future of sustainable lithium recovery.

How we aim to succeed in recovering lithium from produced waters

Our immediate focus is validating that our technology can successfully recover battery-grade lithium from the fluids produced as a byproduct of oil and gas exploration, otherwise known as produced waters.

Major oil and gas companies are committed to this sector, providing opportunities for great technology vendors.

Cutting-Edge Lithium Recovery, Tested in the Field

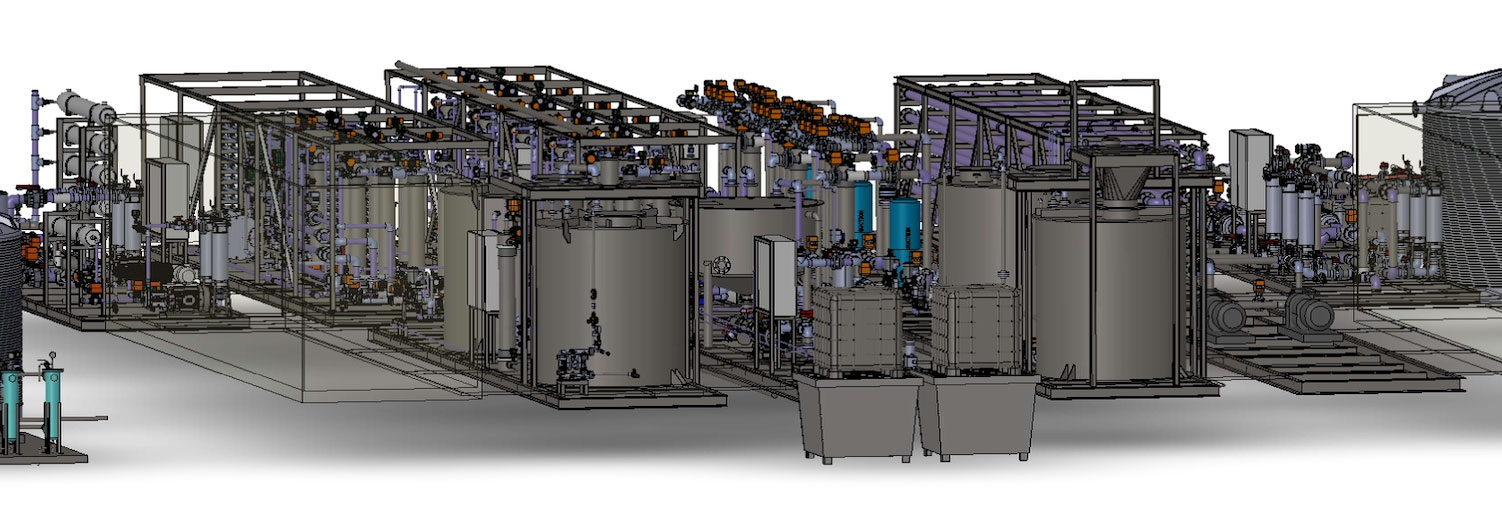

Geo40’s third-generation pilot plant is designed to validate the core elements of our Direct Lithium Extraction (DLE) process across a range of diverse produced waters. It features three core components:

Brine Pretreatment

Refining the feedstock for peak lithium recovery

Direct Lithium Extraction

Unlocking lithium efficiently from oilfield-produced waters

LiCl Concentration

Refining the lithium chloride for downstream processing

By deploying our mobile pilot plant directly at the wellhead, we process fresh brines on-site, in real time, delivering unmatched insights into how a full-scale lithium recovery plant would perform.

We’re bringing next-generation lithium extraction directly to an oilfield near you.

Our Three-Stage Lithium Recovery Process

Our Direct Lithium Extraction (DLE) technology transforms produced water into a valuable lithium resource through a three-step process designed for efficiency and scalability.

Pretreatment

Removing hydrocarbon contaminants from produced water to ensure a clean, optimized brine that is ready for lithium recovery.

Direct Lithium Extraction (DLE)

Extraction of high-purity lithium chloride (LiCl) through advanced multi-cycle processing, maximising yield and efficiency.

LiCl Concentration

Refining and concentrating lithium chloride, preparing it for sale or further conversion into battery-grade lithium.

We believe that we are the only DLE Technology company to offer pretreatment, DLE, and lithium chloride concentration directly at the wellhead so widely across North America.

Scaling Up in Lithium

We plan to commission our next-generation lithium pre-commercial demonstration plant in mid-2025 and deploy it to North America, to an oil and gas-produced water site, late in 2025.

We are working towards being the very best large-scale direct lithium extraction technology partner an oil and gas major could hope to work with.

If you’re an oil and gas producer that is committed to the sustainable recovery of lithium, please get in touch.

The Journey of Our Lithium Technology

At Geo40, every breakthrough begins in the lab, where we rigorously test and refine our theories before scaling through pilot plants and to full commercial deployment.

In 2022, we commissioned our second-generation DLE pilot plant in New Zealand, validating our technology across a diverse range of lithium-bearing brines from around the world. This pivotal step confirmed the viability of our process, paving the way for our mobile pilot plant deployment in North America.

By combining precision engineering with real-world testing, we ensure our Direct Lithium Extraction (DLE) technology is ready to deliver scalable, cost-effective solutions for lithium recovery from produced oilfield brines.

The Imperative for Sustainable Direct Lithium Recovery

Lithium is currently extracted almost entirely through hard-rock mining or evaporation from salt lakes (or salars). Both techniques are widely seen as being environmentally impactful, and there is a strong imperative for sustainable direct lithium recovery technologies.

Salar evaporation

Lithium is sourced from salars, typically located in the Lithium Triangle in Argentina, Bolivia and Chile.

Subsurface fluids are placed into large evaporation ponds to produce a concentrate, which is typically refined in China.

Hard Rock Lithium Mining

Lithium is commonly sourced from spodumene, a lithium mineral derived from pegmatite rock. Li2O concentrations typically vary between 1% - 8%.

The process involves excavating, crushing, and extracting a lithium concentrate, which is typically refined in China.

Typical Direct Lithium Extraction

Direct lithium extraction is the process of recovering lithium from subsurface fluids through a direct physical or chemical process.

It is best practice to reinject the fluids back underground once the lithium has been recovered.

Our Lithium Recovery Process

Going global

Geo40 has successfully processed a wide range of lithium-bearing brine types, initially at our two New Zealand based pilot plants, our North American pilot-plant field tour, and now through the deployment of a new global piloting program.

This new program has been designed to respond to the growing demand for our globally recognised direct lithium recovery technology. Oil and gas majors and significant mining companies are requesting us to validate our technology on their resources.

We believe this program will be effective in strengthening demand for our technology.

Proven Technology for High and Low-Grade Lithium Brines

Through our global piloting work, we have validated that our DLE technology can cost-effectively recover lithium, even when lithium is present in very low concentrations in the brine.

We recently won a technology contest conducted by a reputable global engineering consultancy on behalf of an oil and gas major to pilot lithium recovery from 20-ppm lithium produced water.

We validated on-site that our technology can yield a compelling project here.

“I have been engaged by Geo40 since January 2022 to observe and review the development of their direct lithium recovery technology.

“Their approach, using a mineral sorbent, broadly follows the logic of the CIP process developed for low-grade gold deposit recovery in the 1980s; however, this approach is not without its challenges.

“Much as Geo40 has done at scale with silica recovery, they have cleverly deployed their knowledge and intellectual property to deal with the key solid-liquid separation process steps successfully, and Geo40’s in-house team of chemists, engineers and metallurgists are well placed to deploy their technology at scale in the very near future.

“Their second pilot plant, which has now been running successfully for 12 weeks, has demonstrated to me that they have a very compelling DLE process, and I believe they lead the market in cost-effective recovery of lithium from low to moderate grade brines, which coupled with the wide range of brine chemistries they have trialled makes them a very serious contender in the sector indeed.”

Mike Gunn, Gunn Metallurgy, November 2022.

Next steps

As we succeed with lithium recovery at pilot and pre-commercial demonstration scale, we will do exactly what we did on our silica journey; progressively scale up towards commercial production.

The difference with lithium, in a world desperate for sustainable sources to fuel the electric mobility revolution, is the imperative to move rapidly. We are now talking to potential partners about deployment at pace.